Overview

PROJECT TYPE

Mobile App for Warehouse Scanner

My Role

Lead UX Designer

Deliverables

High Fidelity Wireframes

Handoff to Developers

Update Style Guide

Tools

Figma

Business Opportunity

Build an easy to understand and implement slotting software that warehouses can use to optimize their warehouse floor.

After two years of focusing on our Warehouse Management Software (WMS), Fulfilld decided to tackle another need in the Warehousing Industry - Slotting. Slotting is the process of organizing a warehouse to maximize space and efficiency. Many warehouses are losing money by not optimizing where inventory is put away in the warehouse but in order to slot effectively, we needed to build a highly technical, AI-driven platform that would be more accessible to warehouse operators.

I was the sole designer for this project and worked with precision and creativity, hand in hand with Developers and a Machine Learning Data Scientist to create this clean, intuitive Saas/B2B product.

Solution

Process

“ITEration #1”

From this dashboard users can visit the Configuration Settings to determine a few of the warehouse priorities for slotting and view the Score that the configuration received

Initially the team believed that this could be an additional feature onto Fulfilld’s existing WMS app.

This iteration was put together to use as a jumping off point to. have bigger conversations with the Developers and rest of the Product Team.

We quickly learned that we needed a bigger infrastructure for this technical of a product.

I went back to the white board to figure out more of the pieces that we would need in order for the tool to be effective.

Iteration #2

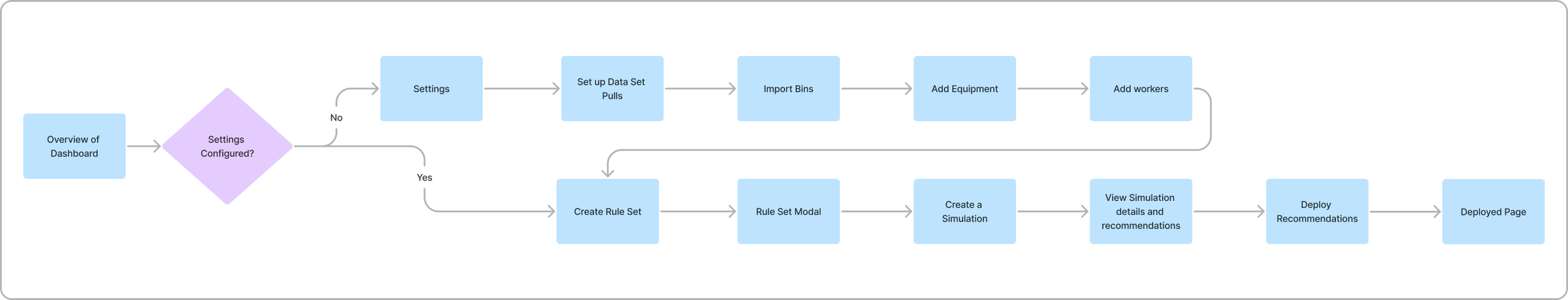

User Flow

This is where I started figuring out more of the main elements that would make up the application.

Dashboard - Your slotting hub with all the recent updates of what is happening in the application.

Data Sets - All the current inventory in the warehouse, on-going orders to understand demand, and locations of which bins the inventory is placed in throughout the warehouse.

Configuration Settings - Users can input different preferences that they have for the warehouse, for example if they want to prioritize inbound or outbound deliveries.

Runs - All of the information from the Data Set + preferences from Settings = a Run. Runs are made up of all the recommended movement for a warehouse to be made in order to optimize the warehouse floor.

User Feedback

Fulfilld began partnering with a company that was interested in using Fulfilld Intelligent Slotting. This was a great opportunity for us to both see how more real-world data was working in the app and get more feedback from users. After conducting interviews with both stakeholders in this company and workers in the warehouse, here were our biggest outcomes and ways to address them:

Problems

“There are some recommendations that we would not make”

“Why isn’t Product X near Product Y?”

“Product Z needs to stay in Zone A”

“I’m not sure if I agree with this movement.”

Solutions

Users need more say in how the algorithm is configured. Instead of just having this in settings, we decided to create Rule Sets an engine where users can add more constraints and preferences. Rule Sets are easier to access than settings and a user can create multiple to make tweaks and changes and compare how they impact the warehouse.

Add Zone and Zone Group functionality to settings. Many warehouses use Zones to keep track of different inventory. So we added a section to the settings where Zones could be added. Then in the Rule Sets users can add behavior for the Zones.

We needed to add more confidence that Recommendations were good moves for the warehouses. Many warehouse managers have been keeping the same inventory in the same place for years. We had to build trust and explain why these moves were being recommended so we added reasoning to the Recommendations like “Pick Efficiency” “Ground Level” or if it was part of a swap.

Swap occur a lot, usually to put a high moving product into a more accessible area. We also marked which items where being swapped and used color coordination to easier indicate the different groups.

An example of Recommendations with these new adjustments

I also wanted to take time with this iteration to better make sure that the Recommendations the workers Deploy are tracked properly. This was especially important to stakeholders to be able to show the impact that Fulfilld was having on their warehouse.

New analytics were added to the Deployments page as it was built out to show the different ways Distance, Time, and Money were saved over different periods of time.

Iteration #3

Conclusions and Next Steps

This was a very big project that took place over two years so not all of the different elements of designing out the application could be shared cohesively in one case study, but I hope to dive deeper into a few of the features soon.

Fulfilld had one go-lives with this application and multiple pilots while I was with the company. In the time one Pepsi warehouse was using the app in a pilot, we were told that the company gained 10% savings by incorporating the changes from Fulfilld Intelligent Slotting.

New Opportunities

The next iteration that I was very excited to design out was focused on making deploying recommendations easier for the warehouse managers. Warehouse workers are so busy and when they have lots of incoming and outgoing orders, slotting is not going to be their first priority. We need to be able to really effectively take the 10-15 minutes they have in a free moment to quickly see the recommendations and decide which ones can be deployed. Once Fulfilld is up and running it is a quick app to use, but this flow of an already working slotting warehouse could definitely be improved.

Next steps would be to build out a deployment engine where users can quickly give a thumbs up or thumbs down to the recommendations. This would serve another purpose as a tool that is constantly learning to help the algorithm create better recommendations for each warehouse.